It is a high-end natural fiber, a very high quality product, whose main characteristics are softness, lightness, resistance, and above all an undisputed thermal insulating power.

WHAT THERE IS TO KNOW :

- An alpaca produces around 2.5 kg of wool per year, with a continuous growth of just under 1 cm per month.

- Its fleece, unlike sheep, does not contain greasy wool, it is said to be dry. It therefore loses very little weight in the wash during its transformation.

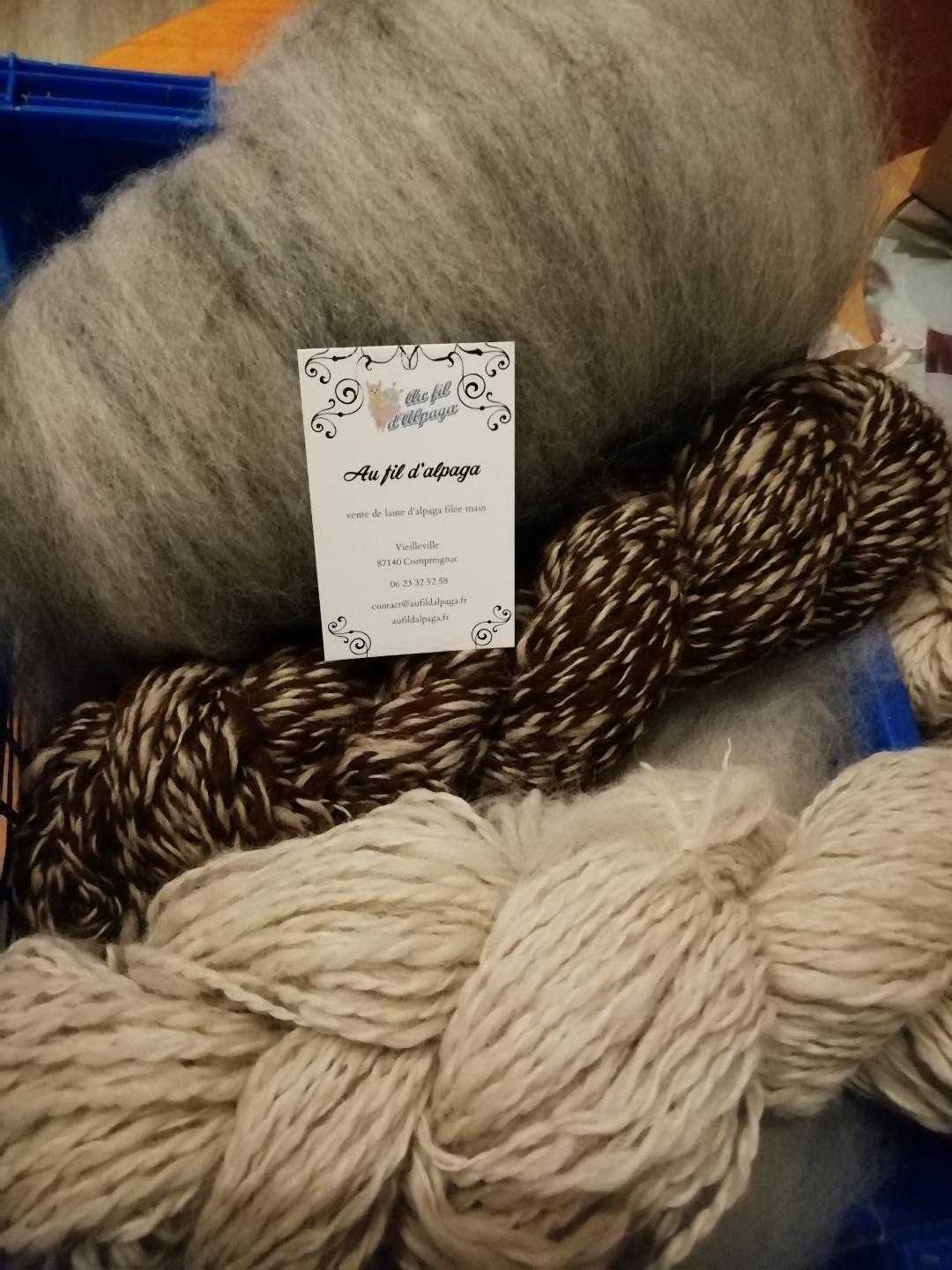

- There are 22 colors in alpacas. However, for marketing, we have grouped them into 6 colors: black, dark brown, light brown, beige, gray, and ecru. These warm, sober and distinguished colors blend very well with each other.

- Alpaca wool is durable over time and the strength of the fibers does not decrease with thickness, making it ideal for industrial processes.

- It contains microscopic air pockets that make it possible to create light clothing with thermal properties.

- It is three times more resistant than sheep's wool, and seven times warmer.

- It is soft and delicate to the touch, due to the cellular structure of the fiber. It produces a soft feel that cannot be matched by other fibers.

- Alpaca clothing does not break, fray, create static electricity, and is easily washable.

- The structure of alpaca wool makes it behave like an insulator, which makes it possible to use it in different climatic conditions.

- Alpaca wool is not flammable unless it is in direct contact with fire.

FIBER TRANSFORMATION :

Many French breeders combine their production to send it to spinning mills abroad (especially Italy): they recover balls or standardized knitted products, at a price that allows them to make a good profit while selling at a price. low ... But their products do not come from their own fleeces, there is no possible traceability, and the industrial treatment does not preserve all the qualities of the fiber.

And above all, the selling prices charged are unfortunately far too low to hope to properly value this exceptional fiber in a French industry respectful of animals and materials ! When a breeder who produces high quality fleeces with animals of high genetic value sells his balls from 50g to € 7 including tax, regardless of where his fiber is processed (and at this price it is not a micro -filature!), it breaks the market and devalues its own production, but also that of other breeders who seek to make a living from the wool business.

The artisanal micro-spinning mills that have developed in Europe (there are two in France) make it possible to transform the fleece fibers by fleece, and therefore guarantee breeders concerned with traceability to recover their own production and to be able to identify animals producing their thread. In addition, these spinning mills work without chemical treatment and with low mechanical constraints: the integrity of the fiber is respected and therefore the durability of wool much greater than in industrial processing. BUT obviously the transformation costs are much higher!

For my part I only want to work and sell my own fibers, and in a traditional way. This is why I sort, card and file my wool entirely by hand.

For ecological reasons, the carding machine and the spinning wheel that I use are not electric.